At the Arctic Subsea Resource Development Summit, industry experts and engineers from several nations met to tackle one of the boldest goals in ocean energy: running underwater machinery in polar seas. A highlight of the day was Esimtech's talk about its next-generation subsea oil production system, built to survive and work well in the harsh Arctic climate.

Meeting the Challenges of the Arctic

Offshore oil and gas work in the Arctic comes with a long list of headaches. Thermometers regularly dip below -40°C, sea ice pushes and pulls on hardware, and crews see only a few hours of daylight for much of the year. Under those pressures, standard subsea rigs often fail or need endless repairs.

Esimtech's answer is a system that starts with a clean sheet of paper and is forged to keep the heat inside, resist crushing ice, and pump oil again and again under a frozen ceiling far from land. Because every battery, pipe, and sensor must be ready the moment the ice splits, the team tested metals, sealants, and cameras in labs even colder than the ocean floor.

Showcasing Innovation: Physical Models & Multimedia Demonstrations

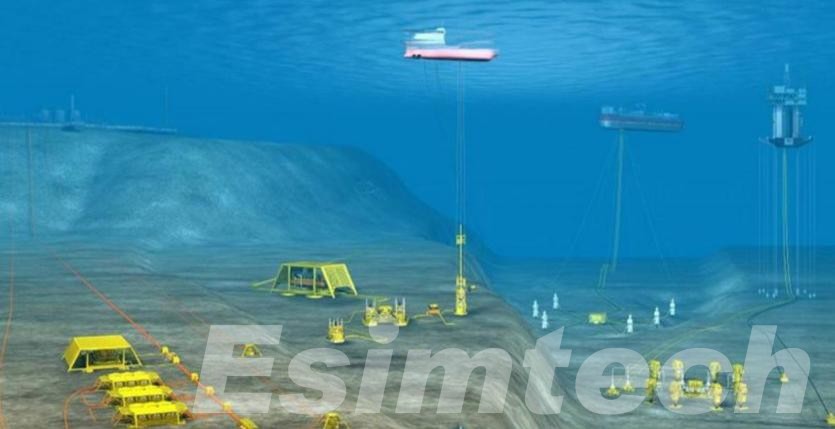

At the summit, Esimtech mixed full-size mock-ups with sharp 4K videos so guests could see each part in action and picture how it would look nine hundred metres beneath shifting ice. Doctors of engineering, regulators, and finance chiefs moved from station to station, turning knobs, listening to pumps, and watching real-time data scroll by, all of which made the pitch far more powerful than a slide deck.

The heart of their booth was a detailed scale model showing how a polar seabed setup would look. It featured risers, manifolds, flowlines, and control pods—all built to slide neatly under shifting, thick ice sheets.

Engineering Highlights: Built for Extremes

One standout part of Esimtech's Arctic line is its use of cryo-proof materials. Every piece—whether seals, housings, or circuit boards—is made with alloys and plastics able to shrug off long spells in the deep-freeze sea.

The team didn't stop there. Instead of the usual narrow beams and thin skins, Esimtech's frame spreads stress over a wide shell with extra ribs, so floating ice shelves or scouring keels hit reinforced armour, not weak spots.

Keeping fluid moving inside lines is still a must. To block hydrates and wax, engineers wrapped pipes in high-tech, layered skins: a light aerogel blanket caged in a hard vacuum jacket, curbing the chill that kills flow.

Smart Monitoring: Real-Time Data from the Deep

Cutting-edge subsea production systems now come with a reliable set of sensors that track temperature, pressure, and flow without pause. Thanks to built-in edge computers, the system picks up odd signs like leaks, sudden pressure drops, or freezing pipes, and shoots instant alerts up to surface crews.

This kind of smart automation embodies Esimtech's bigger promise: a safer, leaner, and more intelligent approach to pulling resources from beneath the waves.

Operational Experience in Polar Waters

Esimtech is already putting these new tools to work in the icy Arctic. At a recent event, the team walked guests through drills carried out in far northern fields, detailing long-test runs and steady operation under thick sea ice.

One highlight involved a subsea module off Norway's northern coast. Even with air chills between -25°C and -35°C and constant ice acting as a moving blanket, the rig logged a full year online and recorded zero mechanical faults.

Looking Ahead: Esimtech’s Arctic Commitment

As the world eyes untapped resources in the Arctic, the need for strong, green subsea tech has never been stronger. Esimtech showed off its latest systems at the recent summit and again proved it can shape-push its gear for future Arctic conditions—and keep leading the field.

Guided by fresh ideas, real-world trials, and a solid grasp of polar engineering, Esimtech is winning trust from governments, operators, and investors who want to tap Arctic energy in a smart, safe way.

Leave a Reply